Ablation process

Solutions

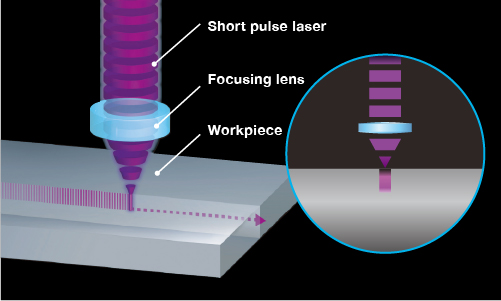

What is Ablation process?

This method focuses laser energy onto a minute area for a very short time, thereby subliming and evaporating the solid.

Features

- Low heat damage processing

- Non-contact process with less impact or load

- Usable for hard workpieces that are normally difficult to process

- Enables narrow street width of under 10 µm

The ablation provides three types of processes - grooving, full cut, and scribing - by adjusting the laser depth.

-

Grooving

・Process that removes the fine wiring layer on the surface of the street with non-contact laser processing and then cuts the remaining substrate with blade dicing. This process reduces chipping and layer peeling and improves throughput.

・Most suitable for low-k film, aluminum nitride (AlN), and alumina ceramics.

・Usable for hard workpieces that are normally difficult to process.

・For details of grooving, click here. -

Full Cut

・Singulation process for wafers less than 200 µm thick using only laser processing. With this process, high-quality processing without chipping or cracking is made possible.

・Most suitable for silicon and gallium arsenide (GaAs).

・For details of full cut, click here. -

Scribing

・Process that creates a thin groove enabling cutting on the dicing street, and then cuts die by applying external stress, such as breaking, etc.

・Most suitable for sapphire.

Process handling equipment

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details