Plasma Dicing Process

Solutions

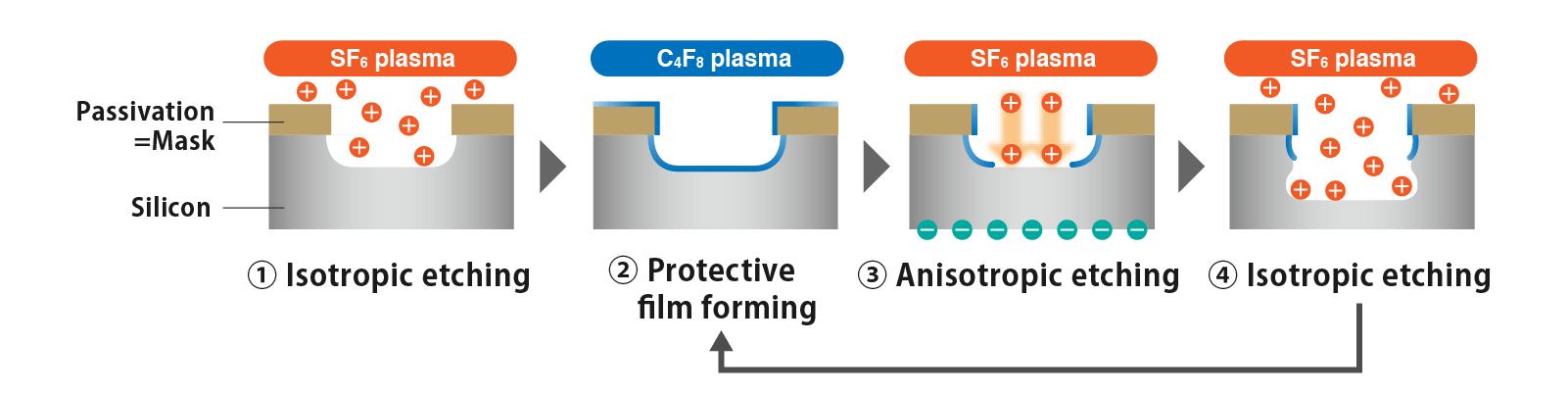

Plasma dicing is processing technology that separates wafers into die (singulation) by performing dry etching under vacuum. The Bosch Process* (see figure), used in plasma dicing, achieves high-speed singulation with a high-aspect ratio even for narrow streets.

In products such as discrete devices and RFID, streets are being made narrower with the aim of increasing the number of die per wafer. In addition, higher productivity than in the past is required for small die devices, which are in high demand for use in mobile devices and IoT applications. Plasma dicing can be used with devices that require high quality, such as automotive semiconductors, which require zero defects.

*method developed in 1992 by Robert Bosch GmbH in Germany

Advantages of plasma dicing

Increased productivity for small die devices

Plasma dicing achieves high UPH even for small die devices since all cut lines on a wafer are processed simultaneously. Because plasma dicing can also be applied to narrow streets, the number of die per wafer can be increased.-

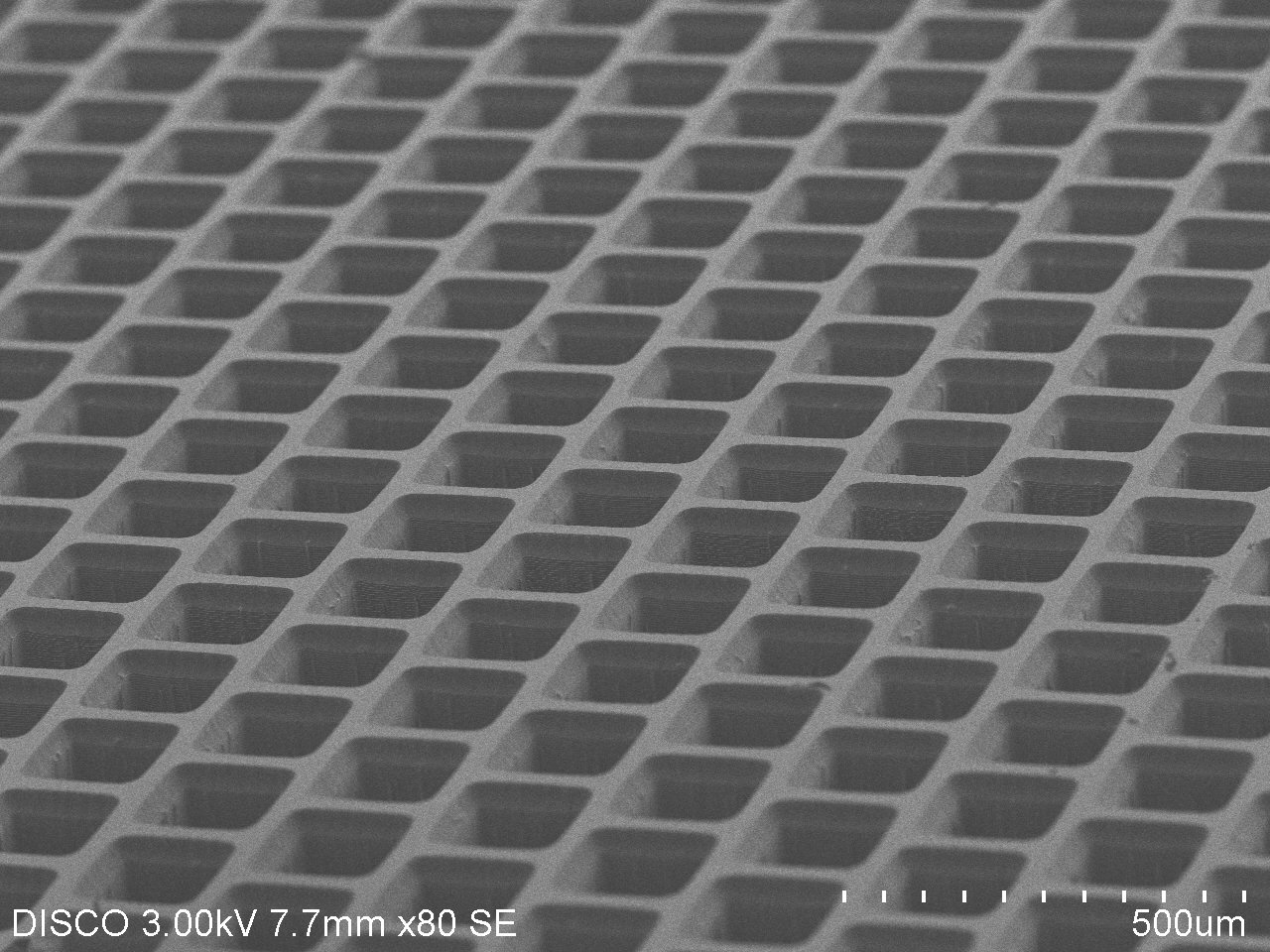

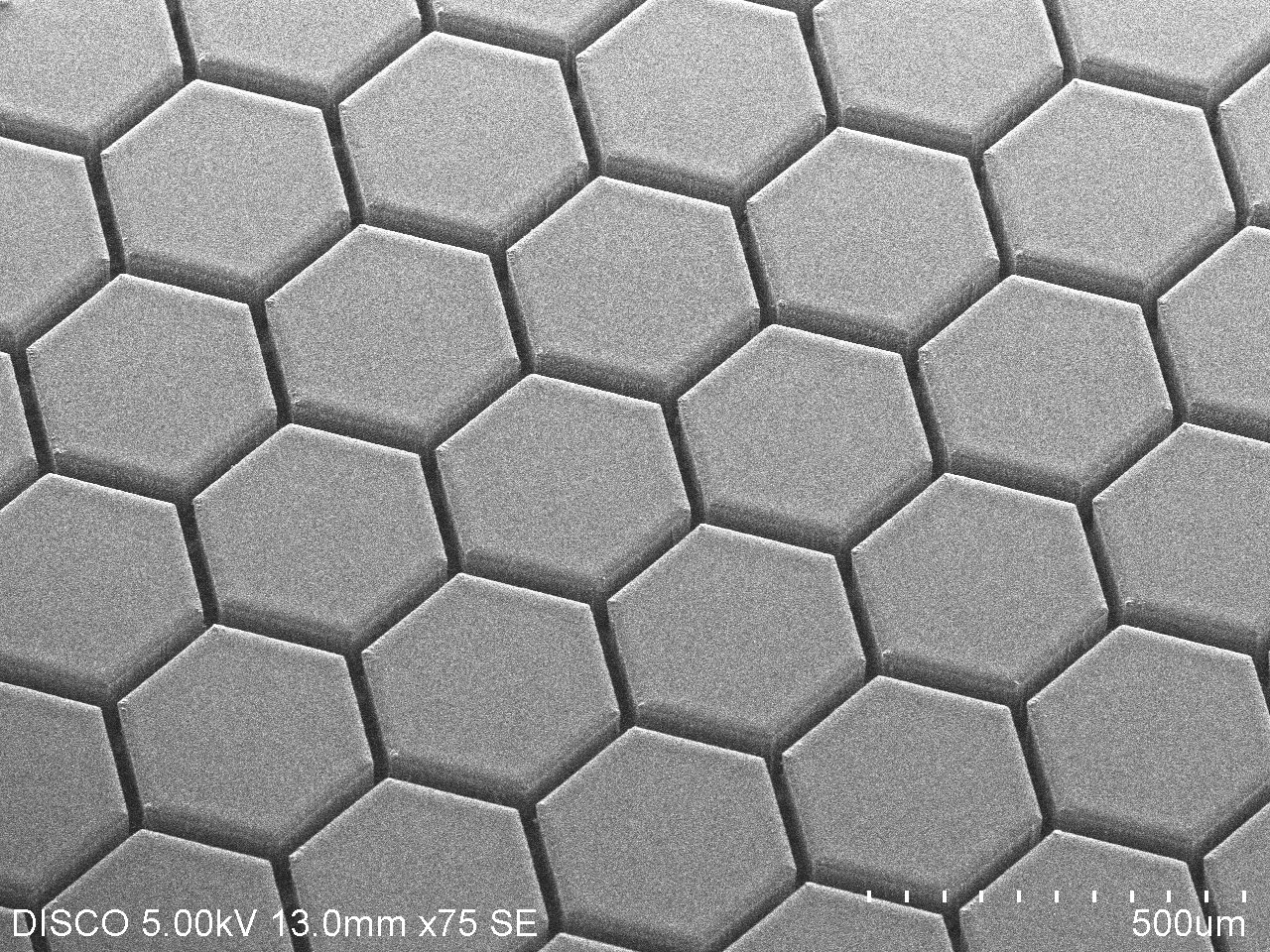

Support for processing of various shapes

Using the dry etching process, plasma dicing is able to achieve singulation based on various mask patterns.

High clean process

Plasma dicing is a dry etching process that uses chemical reactions instead of machining, and therefore does not generate materials such as processing particles or molten debris.Improved die strength

Improved die strength is possible with plasma dicing because it does not cause any mechanical damage and does not have strong thermal effects.

Applications

Total solutions by DISCO

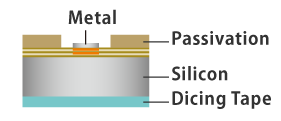

Normal devices contain materials on the street that interfere with plasma dicing, such as film and metal. Therefore, a process that eliminates these materials is necessary as a pretreatment for plasma dicing. With the various processing techniques and applications that it has cultivated, DISCO is able to provide all the processes up through singulation of Si wafers upon which devices have been formed.

Application example:

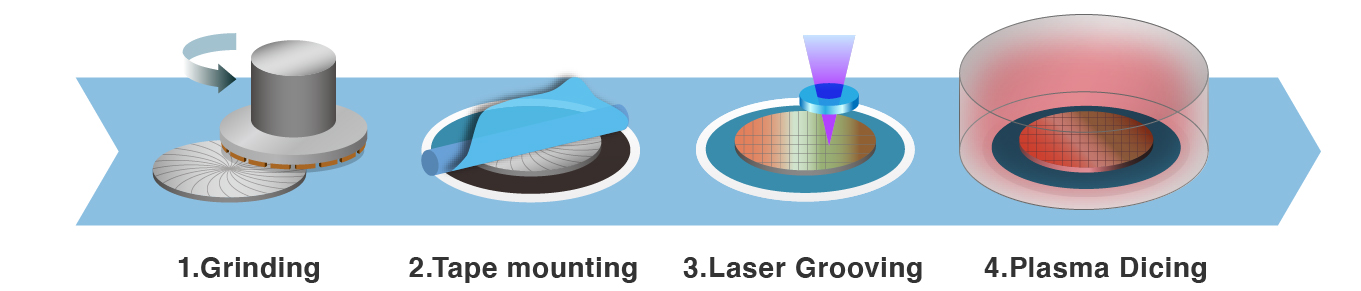

Singulation of Si wafers with metal formed on the street

- Backgrinding: thinning the wafer with a backgrinder/polisher.

- Tape mounting: attaching thin, difficult-to-handle wafers to the tape frame using a mounter.

- Laser grooving: eliminating metal materials such as passivation film or TEG on the street line areas with the laser saw.

- Plasma dicing: performing plasma dicing while the wafer is mounted on the tape frame.

Applications

- Power device

- LED

- RFID

- RF filter

- MEMS

- TVS (Zener diode), etc.

Business partnership with Plasma-Therm in the United States

In April 2016, DISCO formed a business partnership with Plasma-Therm in the United States. Through this partnership, DISCO provides global services including R&D, test cuts, the sale of equipment, and after-sale support using Plasma-Therm plasma dicing equipment.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details