Ultrasonic Dicing

Solution

Ultrasonic dicing, which was developed as a process to support electric parts (ceramics) and optical parts (optical glass prisms, filters, etc.), improves the processability of difficult-to-process materials including glass and ceramics which are difficult to process using blade dicing.

Issues of conventional difficult-to-process materials

Various problems occurred with blade dicing for difficult-to-process materials, including glass, ceramics, metal, and resin.

-

When processing load increases*1 due to blade glazing*2 or loading*3, various defects, including chipping, increased burring, blade breakdown, irregular wear, workpiece burning, etc., occur.

*1 Processing load increases as a result of fine particles or increased feed speed. Increases in processing load can be observed as a rise in the spindle current.

*2 Blade edge abrasive grit wears and abrasive grit is not exposed. Under this circumstance, normal processing is not possible.

*3 A condition where processing particles, tape adhesive, etc., adheres to the blade edge and abrasive grit is not exposed. As with blade glazing, normal processing becomes impossible. - Usable blade variation is limited. To reduce blade glazing and loading, a soft bond type which is quickly consumed is selected, decreasing blade life. In addition, a relatively large grit size (approx. #320 to #600) must be used.

To solve these issues for difficult-to-process materials, ultrasonic dicing was developed.

Ultrasonic dicing process principals

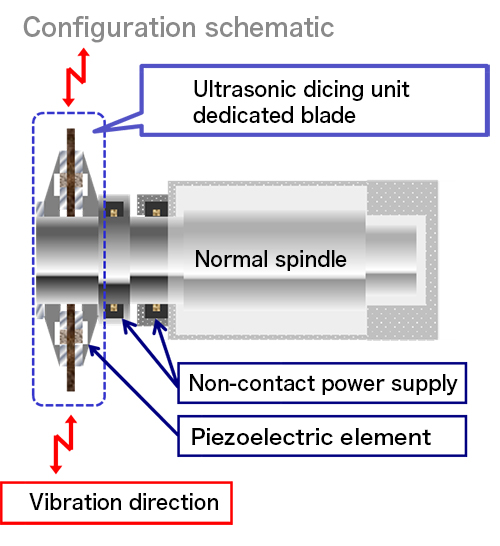

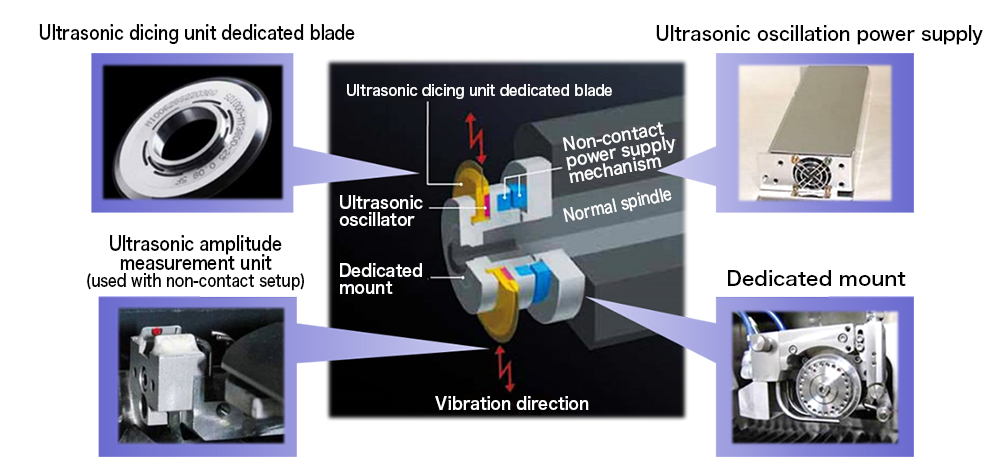

In ultrasonic dicing, a dedicated Φ2-inch blade with built-in ultrasonic oscillator is used. This dedicated blade has a slit on the hub. The blade edge vibrates outward from the center without transmitting vibration to the spindle itself, and the blade outer diameter expands and contracts.(Fig. 1)

Fig. 1. Ultrasonic vibration generation mechanism

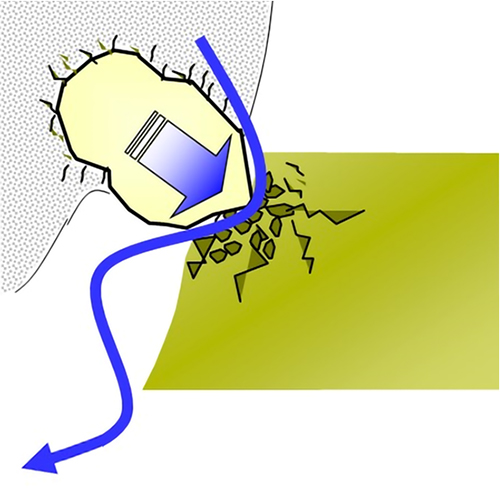

Ultrasonic vibration causes the blade to expand and contract towards the center, causing the abrasive grit to repeatedly collide with the workpiece with high acceleration in a short time (Fig. 2). As a result, a fracture layer is generated in the direction of the blade center, which reduces the processing load significantly.

In addition, since this vibration creates a gap between the blade and the workpiece, abrasive grit cooling conditions greatly improve, and processing quality and blade life is improved by preventing blade loading and glazing.

Fig. 2. Ultrasonic dicing process mechanism

-

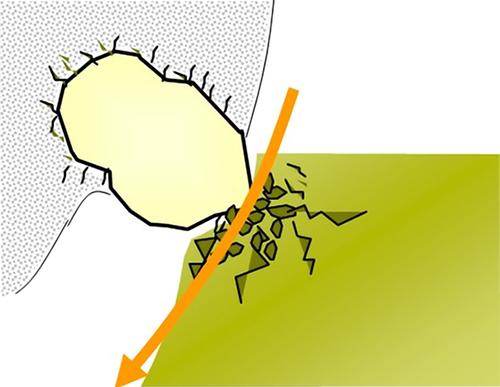

General cutting process

-

Ultrasonic dicing

Advantages of Ultrasonic Dicing

There are numerous advantages as a result of lowering the process load and improving grit cooling conditions

-

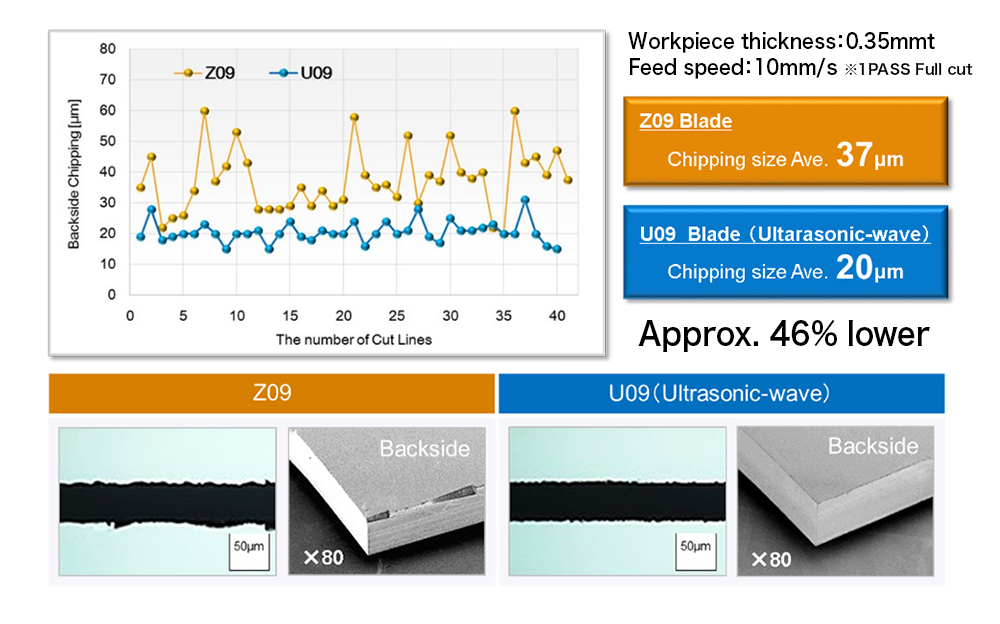

Sudden chipping can be reduced by maintaining the cutting ability while keeping blade consumption relatively low. In the SiC full cutting test, chipping was reduced by almost 50%.

- For ductile materials such as resins and metals, process failure (increased burring) caused by blade loading can be prevented through the cooling effect and ultrasonic strong vibration because it prevents cutting particles from adhering to the blade edge.

- Electroformed bonds, on which blade loading and glazing often occurs, can be used with high intensity, and a finer grit size can be used to allow for thinner blades. As a result, the yield rate can be improved.

Ultrasonic Dicing Unit Dedicated Blade

In order to perform ultrasonic dicing, an ultrasonic oscillation power supply, amplitude measurement unit, dedicated mount and cap, and dedicated software are necessary. They are referred to as whole as the ultrasonic dicing unit. This can be installed on not only new equipment, but also equipment already in use through on-site retrofitting. You can also select resin, metal, or electroformed blade bond types, just like with standard blades. We are prepared to meet a variety of customer demands.

Applicable Equipment

Compatible with DAD3000 series and DFD6000 series dicing saws.

Contact us for details.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details