The advantages of non-contact setup (NCS)

Application processing examples

The setup function detects the height of the blade above the chuck table. Here, we are introducing the advantages of non-contact setup, an optional feature of DISCO dicing saws.

Chuck table setup (standard feature)

By bringing the blade into contact with the upper surface of the chuck table, blade height is detected using electrical conductivity.

<Disadvantages of contact setup>

- It cannot detect when there is workpiece on the chuck table (during processing).

- A non-conductive blade cannot be used.

- Contact can damage the blade.

Non-contact setup (optional feature)

Non-contact setup detects blade height by using a transmission sensor, without the blade contacting the chuck table upper surface.

<Advantages of non-contact setup>

- Setup can be performed during processing.

- No damage to the blade.

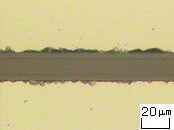

Even immediately after setup, processing is possible without deterioration in quality.

-

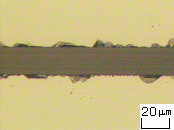

After chuck table setup

-

After non-contact setup

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details