GaAs Wafer Thinning with Tape Securing Process

Application processing examples

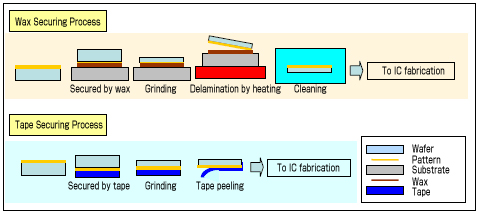

Typically, GaAs wafers are secured with wax, but based on the application, tape securing for grinding is also possible.

Processing examples

GaAs is an easily damaged material, so typically wax securing is chosen for grinding due to its strong retaining force. However, if the wheel, processing conditions, tape, and other variables are chosen properly, tape secured grinding is also possible.

Wax securing process

Advantages

- Low risk of wafer breakage during grinding.

Disadvantages

- High probability of variation in thickness due to difficulty in precisely applying wax.

- A cleaning step is necessary to remove the wax after peeling and grinding.

- High risk of wafer breakage during cleaning.

Tape securing process

Advantages

- Process is simple when compared with wax securing.

- Low probability of variation in thickness due to high precision securing method.

Disadvantages

- High risk of wafer breakage when grinding if suitable conditions are not selected.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details